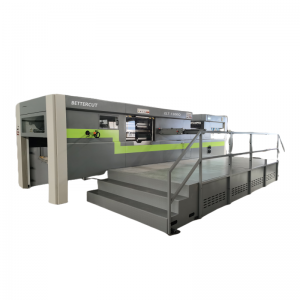

Semi automatic die cutting and creasing machine ELT-1450B

Short Description:

When you are looking for a semi-auto die cutter, “BETTERCUT” ELT-1450B is always the first choice for our customer, ELT-1450B semi-auto die cutter is ideal for die cutting a wide range of materials such as cardboard, litho-laminated, corrugated and semi-rigid plastic. Solid in construction, they have been designed to meet the demand for medium or short runs, with minimum adjustment and response times and be strict in accordance with CE standards. Format: 1480×1080mm, 4500 sheets/hour, 300ton cutting force, high-pile delivery, stripper or without stripper for option.

Product Detail

Product Tags

FEEDING SECTION

1.Effective manual feeding system.

2.Side guide to position paper pile center.

3.Automatic sheet pile lifting system.

4.Various sizes and thickness, wide range

DIECUTTING SECTION

1.Pneumatic lock-up system to ensure safe and operator friendly changing of the die-cutting plate.

2.Central position system for quick stripping die set up and job changeover.

3.Adopting the world famous brand of Bearings (NSK from Japan) and electronic components (Siemens, Omron and Schneider), precise control and die-cutting process can be achieved.

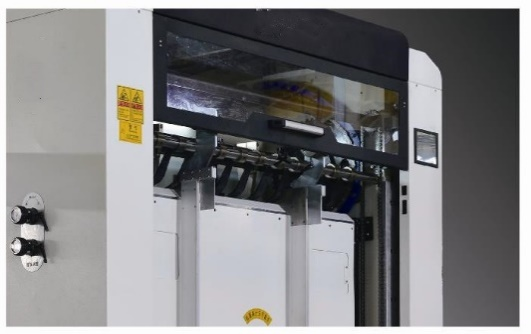

DELIVERY SECTION

1.Photovoltaic device for safety entrance and operation.

2.High-pile pallet delivery.

3.Side and front joggers to ensure neat stacking.

4.Optional function: tape inserter with counter.

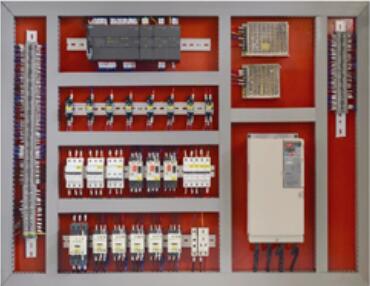

Electrical Section

1.Adopts electrical components of world famous brands for better performance and in time&local after-sale-service and maintenance.

2.Siemens’s Latest PLC technology to ensure safe and trouble free running.

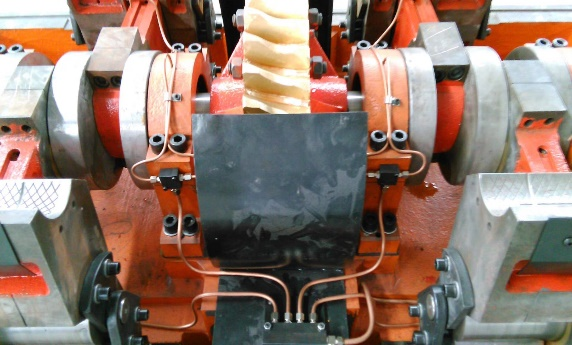

Main Driving System

1.Mono-block casting chassis to reduce less vibration and achieve more stable performance and longer lifespan.

2.Deepened oil tank to make part of worm wheel working under lubrication oil for better lubrication.

Main Chain Drive

Heavy load and highly precise chain (RENOLD from UK) to achieve high tensile strength and wear resistance.

| Type | ELT-1450 |

| Max. paper size | 1480×1080mm |

| Min. paper size | 550×480mm |

| Max. cutting size | 1450×1050mm |

| Cutting pressure | 300 ton |

| Paper type | Corrugated board≦9mm, cardboard≥250g |

| Cutting accuracy | ±0.5 mm |

| Max. mechanical speed | 4500s/h |

| Cutting rules height | 23.8mm |

| Pressure adjustment | ±1mm |

| Min. front margin | Gripper ≥8 mm |

| Total power | 20.5kw |

| Machine dimension | 6270×3450×2340mm(include platform) |

| 4778×2805×2330mm (not include platform) | |

| Total weight | ~17t |

| No. | Item | Brand |

| 1 | PLC | Siemens, German |

| 2 | VFD | YASKAWA, Japan |

| 3 | Gripper bar chain | IWIS, German |

| 4 | Touch screen | Siemens, German |

| 5 | Photoelectric / amplifier | Panasonic, Japan |

| 6 | Base crankshaft bearing | NSK ,Japan |

| 7 | Gripper | 65Mn |

| 8 | Base / upper and lower platform | QT500 |

| 9 | Circuit breaker / contactor | Schneider, France |

| 10 | Encoder | OMRON,Japan |

| 11 | Pneumatic clutch | OMPI, Italy |

| 12 | Photoelectric switch | OMRON, Japan |

Professional wooden package and skilled loading teams