High Speed Fully Automatic Flute Laminator ELT-1650ZH

Short Description:

- This machine integrates servo compensation system and motion control system, optimized design, uses multiple sets of photoelectric sensors to detect the relative position of the backing paper, controls the speed of the servo motors on both sides of the surface paper, and compensates independently, so that the surface paper and the bottom paper are synchronized and accurately pasted. Adhering to the “people-oriented” design concept, the operation is simple, and the adjustment of the lamination synchronization system can be automatically completed just by entering the paper size.

- Servo control compensated positioning. One key adjustment.

- Max Speed 12000 Sheet/Hour

- Fully intelligent automation

Product Detail

Product Tags

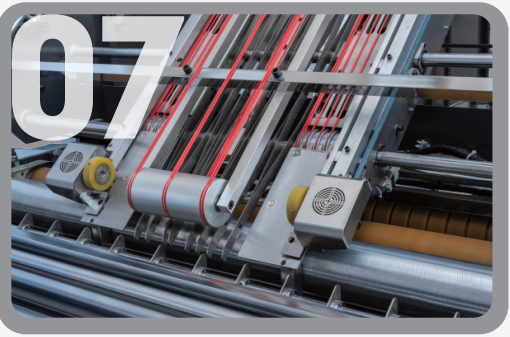

Equipped with high-speed dedicated four-suction and four-feed feeder head, the angle and height of paper pick-up nozzle and paper-feed nozzle can be adjusted. The inclination of the paper line can be adjusted to the left and right to ensure that the paper runs smoothly at high speed.

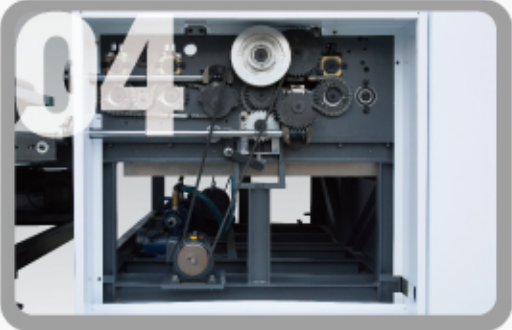

Adopt servo motor control system, and the suction can be adjusted to ensure smooth output of corrugated paper and paperboard and simple operation.

Two face paper feeding modes, free choice of single-sheet feeding and overlapping feeding.

Using 4 cm thick cast iron wallboard, it is not easy to deform and the transmission is more stable.

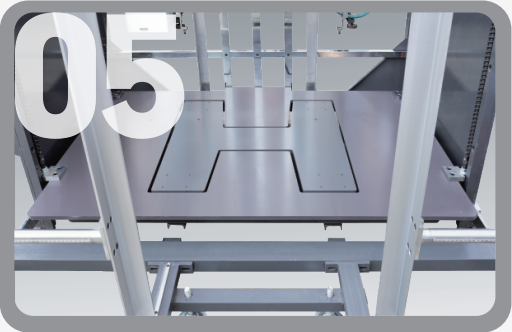

Pre-stack pile of paper under the condition of non-stop, improve efficiency. The special design of pre-stack paper frame, convenient and efficient.

Adopt special anilox roller design, fine grinding to ensure uniform coating. The lower roller is cleaned with water roller.

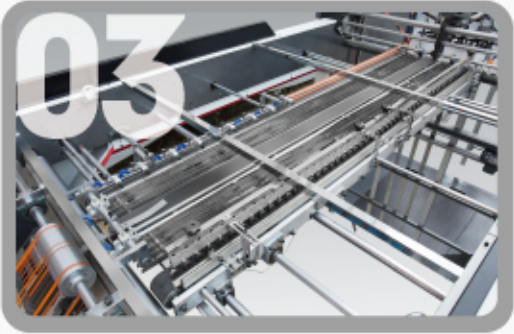

Multiple sets of photoelectric sensors are used to detect the relative position of the bottom paper, and the motors on both sides of the top paper are controlled to perform independent compensation actions, so that the top paper and the bottom paper are accurately attached.

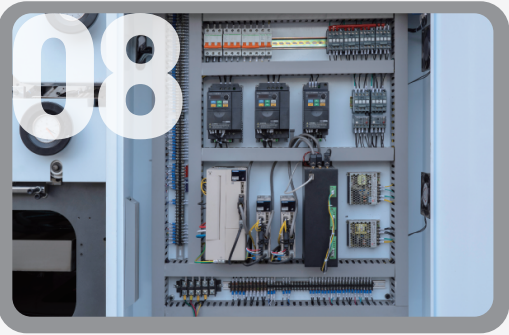

With the combination of human-machine interface and PLC, various information such as parameter setting, operation speed, fault detection, abnormal alarm and other information are displayed on the screen to ensure the stable and efficient operation of the whole machine.

| Model |

ELT-1650 ZH

|

| Max paper size | 1650*1450mm |

| Min paper size | 400*380mm |

| Precision | ±1.5mm |

| Speed | <12000sheet/h |

| Weight of top paper | 180-500g/㎡ |

| Type of bottom paper(Corrugated paper/Paperboard) | A.B.C.E.F(Corrugated paper, Paperboard, Grey paper) |

| Total power | 25kw/380v |

| Weight | 11.5t |

| Size(L*W*H) | 15*2.6*2.4m |

At ELITET MACHINERY, you can expect satisfactory customer service with long tradition. We are highly devoted to the most optimal solid and liquid separation solutions to meet your specific needs. We have the effective service system to ensure professional and flexible management of any affairs.

Professional wooden package and skilled loading teams