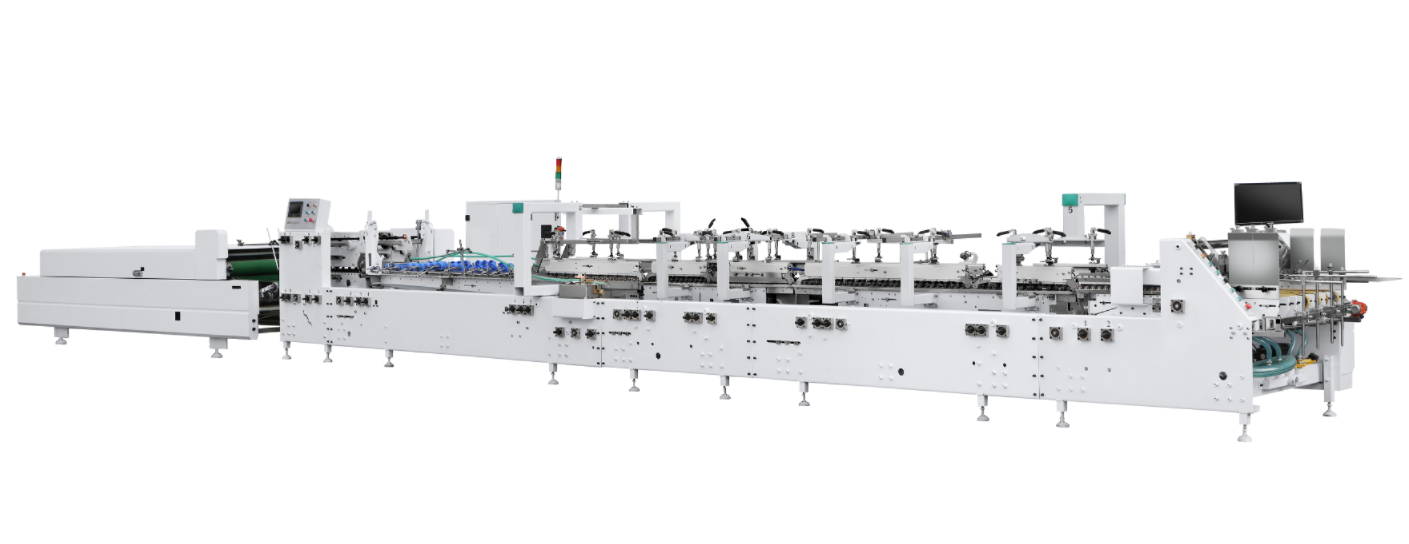

High Speed ELT-1100 multi function fold gluer for cardboard and corrugated board

Short Description:

Intelligent design,the six sections of feeder(paper alignment)、pre-folding、lock-bottom、folding、transfer. conveyor can be completely free to choose configuration, 4&6 corner and other boxes are easy to add

A new generation of high speed machine adopt wedge belt wheel transmission, speed up to 400 m/min

Apply to the card paper and corrugated paper boxes, multi-purpose machines

Product Detail

Product Tags

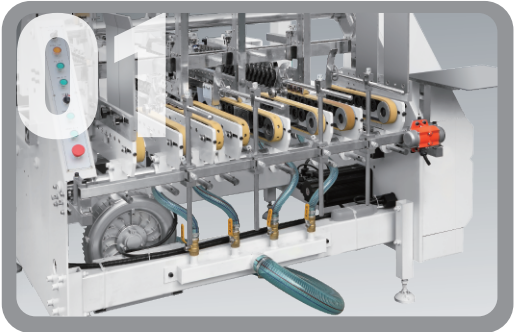

1.Independent servo motor drive, high speed operation is accurate transfer paper, so as to achieve the best capacity;

2.Large micro adjust paper knife, lateral baffle width adjustment is convenient;

3.Vortex pump configuration independent suction chamber and the valve, increase rubber belt paper friction with smooth paper;

4.Scalable paper stack at the back of the support for longer box.

1.Independently adjustable side gauge, and wallboard unparallel along a parallel guide bracket drawing paper delivery, ensure paper parallel alignment;

2.Both sides can realize alignment function from the device, the operation is simple rapid.

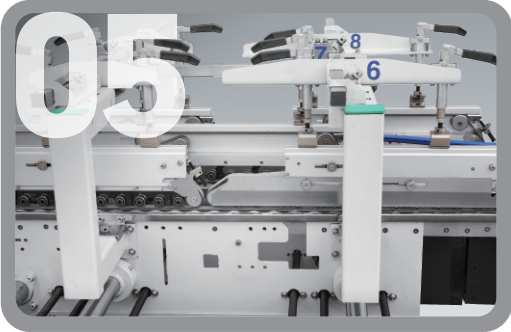

1.180 °folding for the first creasing line,and 135 °folding for the third creasing line;

2. The pre-folding device of the first and third creasing line.

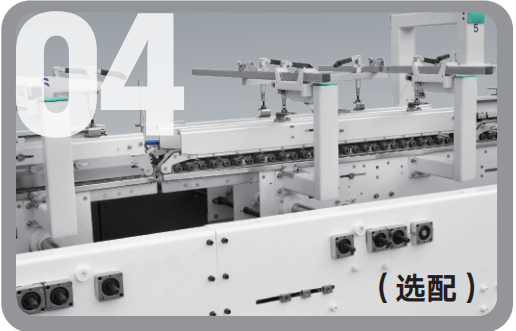

Optional

1. Intelligent electronic hook system, servo motor drive control can adjust the direction of movement of folding hook, to adapt to the length of the folding, complete folding back on peg at the same time, realize the lock bottom, before, after special folding function, such as meet the requirements of a variety of different boxes;

2.Three groups of wallboard, overall and can realize multiple removal; Variable functions,advanced design, easy to operate.

1.Equipped with hook combination adjusting mechanism, the ideal design, easy to operate, high stiffness spring hook to ensure smooth accurate action;

2.Adjustable hook device, modular design, significantly reduced the transform box type of set-up time, convenient installation and transformation of attachment;

3.Configuration high elastic hook and hook box module.

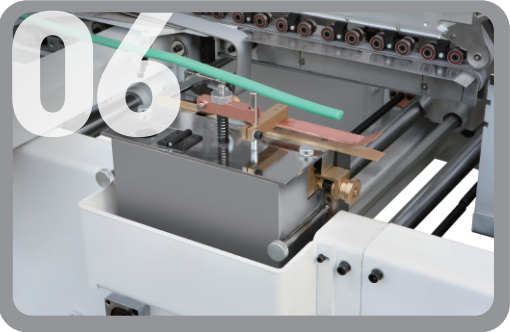

1.The upper gluing tank using electronic spray adhesive system, according to the model select configuration of two or three sets of cold glue guns;

2.Other top electronic spray adhesive system configuration can choose according to the needs of aircraft configuration;

3.The lower gluing tank of each side, a large capacity design, high-speed don't jilt glue, not leak adhesive.

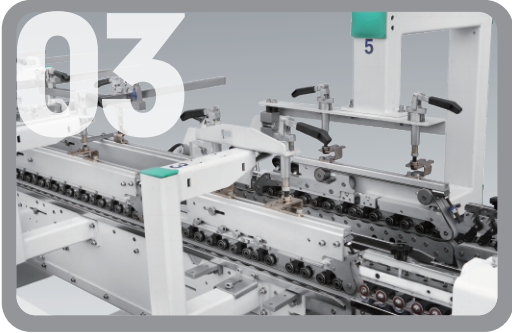

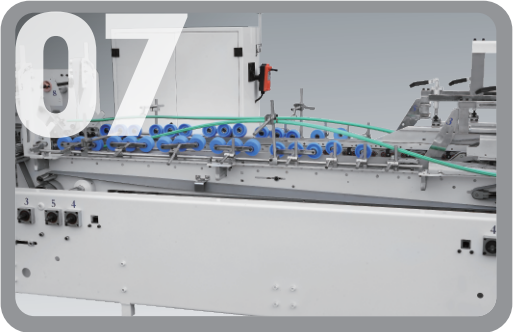

1.Accurately completing the second line, the fourth line 180°combination; Around 180°abduction angle is adjustable, with a belt transmission device, which can effectively ensure the parallel alignment, folding carton sample accurately in closed;

2.Two sets of bracket the upper conveyor belt width is 25mm,the lower conveyor belt width is 25mm&34mm,the kidnapper width is 30mm&40mm&50mm;

3.Equipped with the belt tension automatic control system, easy to tear open outfit.

1.Two sets of bracket, the belt width is 25 mm is equipped with the belt tension automatic control system, easy to tear open outfit;

2.Automatic tracking count, kicking, insert paper automatically detect outage alarm;

3.Configuration lock-bottom module according to the machine model and carton type;

4.Carton transfer adjustment continuous automatic box module.

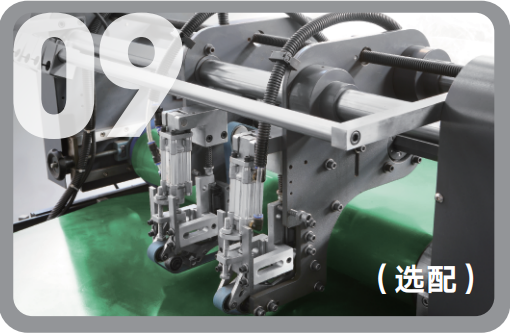

Optional

1.The front-end of conveyor section is equipped with pneumatic box module, driven by pneumatic with photoelectric, two sets of belt bracket interactive action, ensure the carton perfect accumulation;

2.Back stacking corrector, reset the carton position, to ensure the carton into the converyor section,smooth rhythm.

1.Independent motor drive; Manual and automatic operation mode;

2.According to the different length of the box, conveyor belt pressure driven by motor, configuration automatic correction device; Pressure adjustment equip with pneumatic pressure adjusting device, convenient adjustment ;

3. The total length is 5.6m, effective delivery length is 3.6m, to extend the time and improve the quality of the adhesive.

| Model | GSF-850/1100/1250/1450 |

| Materials | Paperboard,A.B.C.E.F.Corrugated board,Flat mouth box |

| Box | straight lne,double sided,bdk bottom box,CDbax,4&6corner box, flat mouth box |

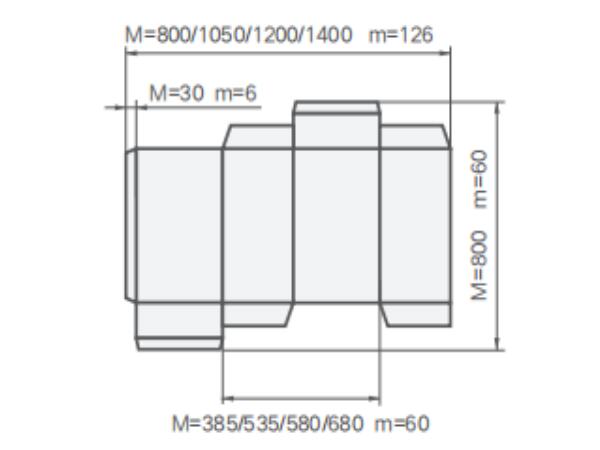

| Straight Line | GSF-850(max):800 ×800mm (min):126×60mm GSF-1100(max):1050×800mm (min):126×60mm GSF-1250(max):1200×800mm (min):126×60mm GSF-1450(max):1400×800mm (min):126×60mm |

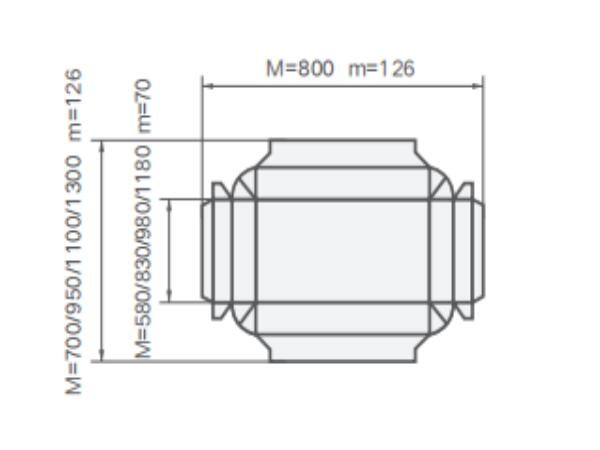

| Double Sided | GSF-850(max);700 ×800mm (min):126×126mm GSF-1100(max);950×800mm (min):126×126mm GSF-1250(max):1100×800mm (min):126×126mm GSF-1450(max):1300x800mm (min):126×126mm |

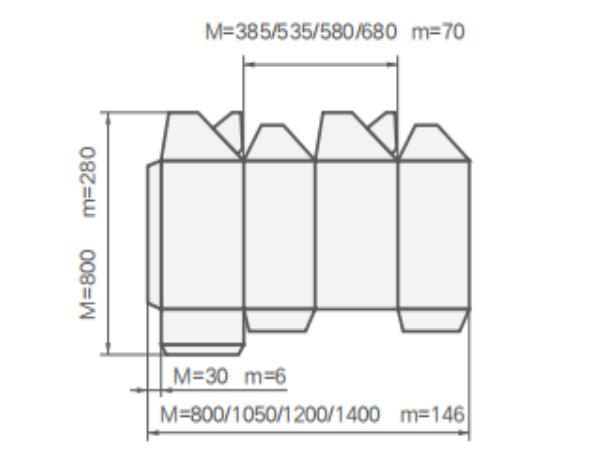

| Lock Bottom Box | GSF-850(max): 800×800mm (min):146×280mm GSF-1100(max):1050×800mm (min):146×280mm GSF-1250(max):1200×800mm (min):146×280mm GSF-1450(max):1400x 800mm (min):146×280mm |

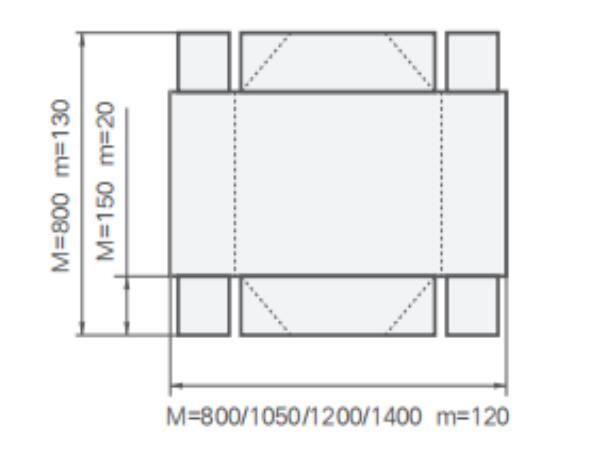

| 4 Corner Box | GSF-850(max): 800×800mm (min):120 ×130mm GSF-1100(max):1050×800mm (min):120×130mm GSF-1250(max):1200×800mm (min):120×130mm GSF-1450(max):1400×800mm (min):120×130mm |

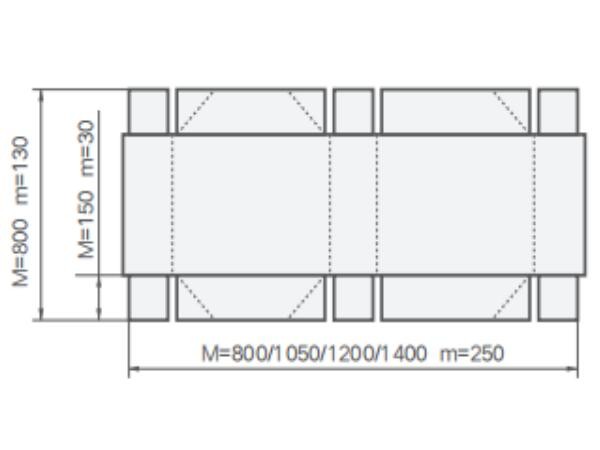

| 6 Comer Box | GSF-850(max): 800×800mm (min):250×130mm GSF-1100(max):1000×800mm (min):250×130mm GSF-1250(max):1200×800mm (min):250×130mm GSF-1450(max):1400×800mm (min):250×130mm |

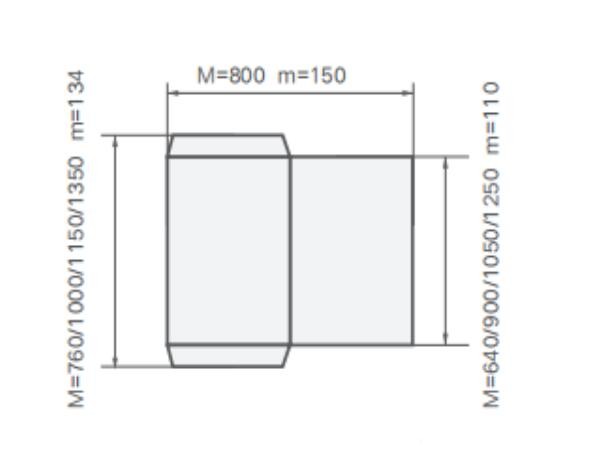

| CD Box | GSF-850(max); 760×800mm (min):134×150mm GSF-1100(max):1000×800mm (min):134×150mm GSF-1250(max):1150×800mm (min):134×150mm GSF-1450(max):1350×800mm (min):134×150mm |

| Flat Box Size | GSF-850(max): 800 ×800mm (min):* GSF-1100(max):1050×800mm (min):* GSF-1250(max):1200× 800mm (min):* GSF-1450(max):1400× 800mm (min):* |

| Max Speed | 400m/min |

| Total Power | GSF-850: 20 KW GSF-1100:22 KW GSF-1250:24 KW GSF-1450:26 KW |

| Machine Size | GSF-850 18×2.0×1.5M(L×W×H); 8.5Tons GSF-1100 18×2.3×1.5M(L×W×H); 10.5Tons GSF-1250 18×2.5×1.5M(L×W×H); 11Tons GSF-1450 18×2.7×1.5M (L×W×H); 11.5Tons |

| Compressor PressureEnergy And Capacity | GSF-8506 6 bar,10m³/h; 60L GSF-1100 6 bar,10m³/h; 60L GSF-1250 6 bar,10m³/h; 60L GSF-1450 6 bar 10m³/h; 60L |

Straight Line Box

Lock Bottom Box

4-Corner Box

6-Corner Box

Double Sides Box

CD Box

Professional wooden package and skilled loading teams