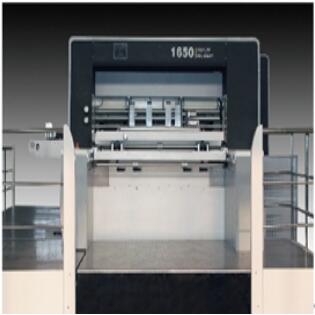

High speed 5500sheets/hour large format ELT-1650G automatic flatbed lead edge feeding die cutter with full stripping

Short Description:

“BETTERCUT” ELT-1650G is our company’s very advanced and high end product, with a speed of 5,500 sheets per hour, it can help our customer to achieve bulk production in a high efficiency way. ELT-1650G adopts the double servo motor control at the feeding section to ensure a very high accurate paper feeding and easy for adjustment, and this structure can prevent the scratches effectively, meanwhile it adopts the most advanced technology of gear drive mechanism, which can make sure the machine running at a high and stable speed.

Product Detail

Product Tags

FEEDING SECTION

1.Lead edge feeder allows consistent and precise feeding of wide range corrugated board.,

2.Vacuum suction adjustment achieved through inverter for wide range from F flute to double wall.

3.Servo motor control for accurate paper feeding

FEEDING TABLE

1.Left and right side push lays to ensure accurate alignment and power registration.

2.Adjustable rubber wheels achieve precise paper feeding.

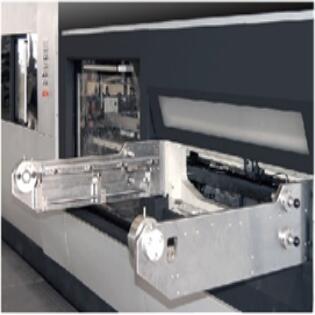

DIE-CUTTING SECTION

1.Pneumatic lock-up system to ensure safe and operator friendly changing of the die-cutting plate.

2.Centerline system for quick stripping die set up and job changeover.

3.Human machine interface for monitoring machine’s working situation and touch screen control panel for easy operation and malfunctions diagnosis.

4. Gear drive for stable and fast machine running

5.Heavy duty pneumatic clutch with overload protection for stable and safe machine running.

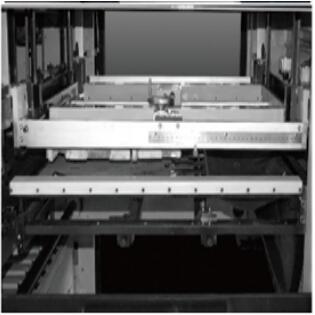

STRIPPING SECTION

1. Centerline system for quick stripping die set up.

2,.Double stripping system and male/female stripping die for different stripping jobs.

3.Front waste separator to achieve full stripping and front waste transferred to the machine drive side by conveyor belt.

DELIVERY SECTION

1.Non-stop delivery system for continuous productivity.

2.Photovoltaic device for safe operation and entrance.

3.Delivery control panel with icons for easy operation.

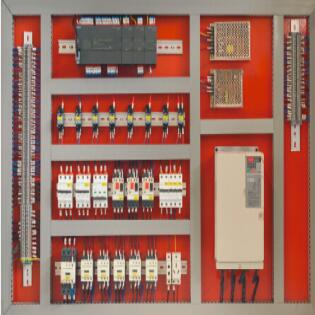

ELECTRICAL CONTROL PART

SIEMENS latest PLC technology, VFD (YASKAWA from Japan) and other electronic components of well-known brands to ensure stable and safe operations.

| Maximum paper size | 1650*1200mm |

| Minimum paper size | 650*500mm |

| Maximum cutting size | 1630*1180mm |

| Maximum cutting pressure | 450 T |

| Stock range | C, B, A Flute and double wall or Corrugated board up to 9mm |

| Cutting precision | ±0.5mm |

| Maximum speed | 5,500 s/h |

| Height of cutting rules | 23.8mm |

| Pressure adjusting range | ±1.5mm |

| Minimum front margin | 10mm |

| Inner chase size | 1660*1210mm |

| Total power | 37KW |

| Dimension(including the work platform) | L*W*H: 11200*5560*2550mm |

| Dimension( excluding work platform and chase loader) | L*W*H: 9200*3200*2550mm |

| Machine’s weight | 38 T |

Professional wooden package and skilled loading teams