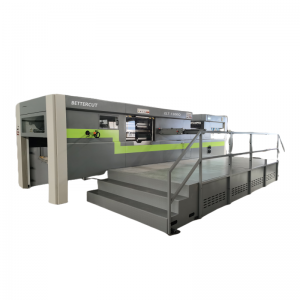

High Quality ELT-1060HT Hot foiling stamping & Embossing & Die cutting machine

Short Description:

ELT-1060HT Automatic Platen Hot Foil Stamping & embossing & Die Cutting Machine is our company high end product, tt can run large format die-cutting as well as stamping with 3 longitudinal and 2 transverse foil pull system. High precision, high speed, easy to operate, quick make-readies, durability and stable performance. Features that make the machine one of the best options when choosing

Product Detail

Product Tags

1.Longitudinal foil feeding:

Independent foil feeding by three servos, the external foil collection can directly pull out the waste foil to the outside of the machine, and the brush wheel foil collection method is not easy to break the gold foil, and is equipped with an external foil collection waste foil collection. The rewinding system is convenient and reliable, which greatly improves the production efficiency and reduces the labor intensity of the operator; in addition, this model also increases the internal foil rewinding and rewinding function, which is mainly used for larger bronzing widths.

2.Horizontal foil feeding:

Two servo motors are used for independent foil feeding, and one independent servo motor is used for foil winding and waste foil wrapping.

3.The heating part adopts 12 independent temperature zones for uniform and precise temperature control in PID mode, and the maximum temperature can reach 220°C.

4.Using industrial computer and special axis card control for motion control, various combinations of bronzing jumping: uniform jumping, irregular jumping and manual setting, the first two are computer intelligent calculation, all system parameters can be modified on the touch screen and settings, simple, convenient and user-friendly.

Feeder Section

1.Automatic feeder with non-stop system,with pallet and cart direct load.

2.4 lift-up and 4 delivery suckers,designed to handle a wide range of materials from paper to corrugated board,guarantee the accuracy,reliability & smoothness of paper feeding.

3.Double sheet detector.

4.High pile design allows maximum pile height up to 1650mm.

Register Table

1.Side register table with 8 belts.

2.2 register side guides working with pulling and pushing system.

4 .register front lays, independently adjustable.

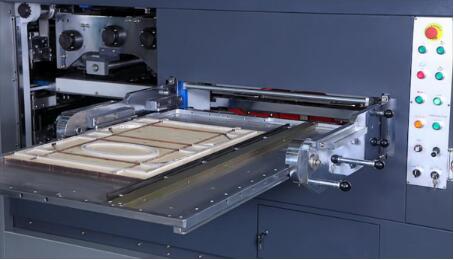

Press And Chase Unit : Die Cut

1.Closed chase with central positioning system device for fast positioning of the die.

2.Cutting plate 5mm thickness(4mm+1mm).

3.Pressure control system, can be easily adjusted through touch screen. It has a security system to avoid any damage in the press.

4.Manual and Automatic lubrication system.

5.Turn-over bracket for cutting chase and honeycomb chase.

6.Pneumatic lock and release system for cutting chase and honeycomb plate.

Foil Stamping System

1.Heating system in 12 temperature zones with individual temperature control.

2.Foil break detector.

3.Films fasten device.

4.Foil unwind device.

5.Honeycomb chase.

Delivery Section

1.Non-stop device with automatic conveyor at delivery.

2.High-pile pallet delivery

| Maximum paper feed size | 1060x760mm |

| Minimum paper feed size | 400x360mm |

| Maximum hot stamping size | 1050X750 |

| Maximum die cutting size | 1050x750mm |

| maximum die cutting speed | 8000S/H |

| maximum stamping speed | 6500S/H |

| maximum operating speed | ±0.10mm |

| Rated voltage | 380±5%VAC |

| maximum working pressure | 450KN |

| Use compressed air | ≧0.25㎡/min ≧0.6mpa |

| stack height | 1600mm |

| Pressure adjustment height range | 2mm |

| Cut line height | 23.8mm |

| Machinable paper thickness | 0.1—2mm瓦楞纸:不大于4mm |

| Hot stamping and foil mode | 3 Longitudinal,2 transverse |

| main motor | 11KW |

| Host total power | 16.7KW |

| Hot stamping heating power | 24KW |

| Dimensions | Without platform and pre-stacker 6200x2500x2750mmWithout platform and pre-stacker 7500x3705x2150mm |

At ELITET MACHINERY, you can expect satisfactory customer service with long tradition. We are highly devoted to the most optimal solid and liquid separation solutions to meet your specific needs. We have the effective service system to ensure professional and flexible management of any affairs.