ELT-1650QZ Full Stripping Automatic Lead Edge Feeding Flatbed Die Cutting Machine

Short Description:

When you want to achieve full production of corrugated board and folding cartons processing, 24 hours a day, seven days a week, the “BETTERCUT” ELT-1650QZ is absolutely an ideal and perfect machine for you.

ELT-1650QZ is our company’s high speed automatic flatbed die cutter in the large format of 1650×1210mm, a speed of 5,200 sheets per hour with 400tons cutting force, suitable for the corrugated board from 1-9mm. This machine includes all the experiences that have been made to date with automatic flat bed die cutter’s: With a new, wider, quieter and very precise lead-edge feeder for max. speed. 18% energy savings due to newly calculated curves for more efficient movements and smoother start and stop time.

Product Detail

Product Tags

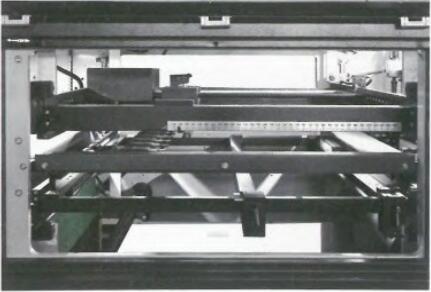

ELT-1650QZ With a fully stripping device equipped, which can remove not only the three sides of the corrugated board, but also the front margin can be also removed. More power in the stripper and improved access by larger window. Improved safety and ergonomics.

Equipped with non-stop batch counter delivery system, you don’t need to worry about the untidy delivery any more, it can help to achieve the highest volumes of jobs.

Integrated casting wallboard.

Durable and not easy to break.

Oversize worm and gear structure, high precision, high speed of die cutting is improved, greatly improve the efficiency

High speed and precise lead edge feeder,prevent the scratches during paper feeding,Variable frequency control air volume adjustment can meet the paper feeding requirements of different corrugated boards.

Overload protection mechanism, to realize the separation of master and slave in case of accidental overload.

Adopts central positioning systerm,quick and convenient adjustment of stripping die. Equipped with front waste removal device, achieve full stripping.

Standard pallet delivery :flexible and high efficiency, Photoelectric detection device,safe and reliable.

Optional: non-top batch counter delivery to increase production efficiency.

| Parameter | ELT-1650QZ |

| Max.paper size | 1650×1210mm |

| Min.paper size | 650×500mm |

| Max.die cutting size | 1620×1190mm |

| Max.die cutting pressure | 400T |

| Paper Available size | 1mm≤corrugated board≤9 |

| Die cutting precision | ±0.5mm |

| Max.speed | 5200s/h |

| Cutting rule height | 23.8mm |

| Range of pressure adjustment | ±1mm |

| Min.front margin | 8mm |

| Max.wood frame size | 1650×1220mm |

| Total power | 38.5kw |

| Dimension(not include platform) | 8750×3200×2610 |

| Weight | ~31t |

Professional wooden package and skilled loading teams