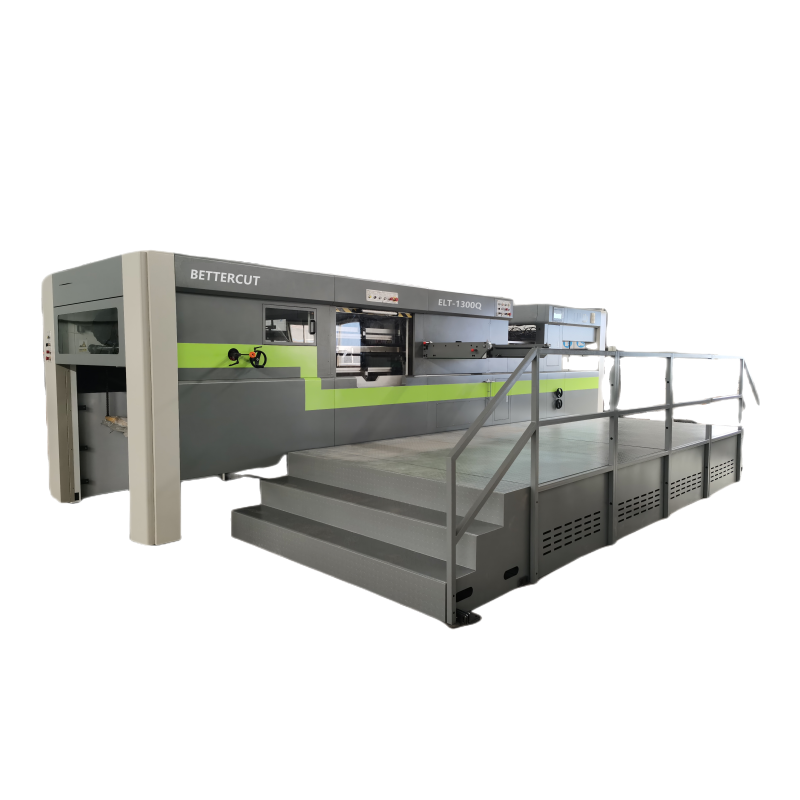

ELT-1300Q Top feeder die cutting machine with stripping

Short Description:

ELT-1300Q automatic die-cutting indentation machine is developed by our company in combination with similar products at home and abroad, which is suitable for corrugated paper and paperboard die-cutting with high precision of one-key conversion. The machine is operated according to different paper thickness, different paper way, with zero scratch and multi-purpose in one machine.

Product Detail

Product Tags

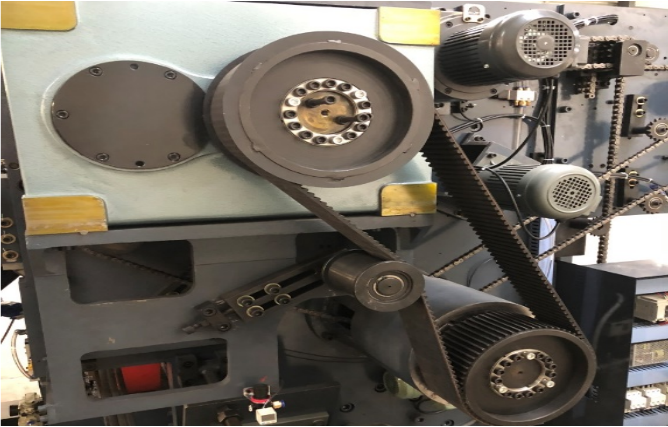

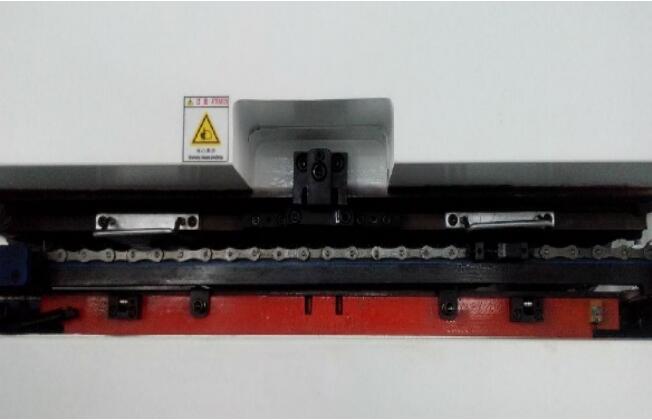

Main drive system

Bearing shell connected ,running is steady.

The main driving system adopts worm wheel and worm gear pair and special designed crank shaft linkage mechanism connected by bearing shell which can reduce locomotive gap, avoid impacting

High precision intermittent mechanism

stable transmission, accurate indexing,

ensuring die cutting accuracy;

The synchronous belt transmission adopt German Iwis brand,

has long service life and high accuracy.

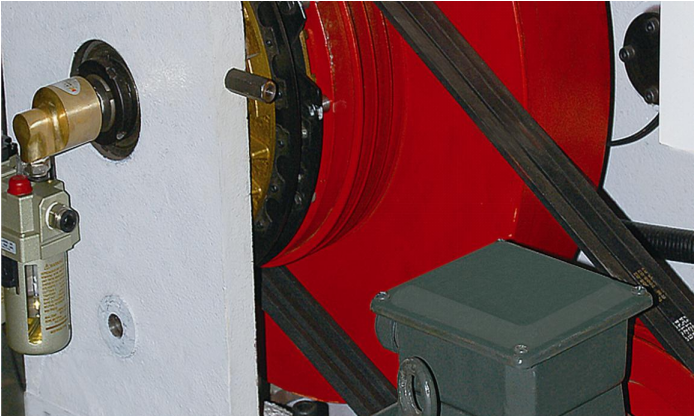

Pneumatic clutch

imported pneumatic clutch. Long service life,

low noise, more stable braking,

fast clutch and large power transmission,

meeting European export standards

Feeding section

Adopts 4 suction nozzles, 5 feeder nozzles,

Servo motor control, more accurate easy to operate and effectively improve work efficiency

Die cutting Section

High die-cutting pressure,ensuring die-cutting quality and easy to demould;Plate frame pneumatic locking system;

Central positioning and rotary plate turning mechanism make plate changing efficient and fast.

Delivery section

The delivery adopts non-stop roller shutter delivery device

High-pile and tidy delivery, greatly improve the production efficiency

Electrical section

Electrical components, electrical switches, PLC and so on are all foreign well-known brands

There are various safe guarding devices that when accident occurs, it will give an alarm by sound and light and shutdown automatically to protect safety of man and machine

The paper feeding system adopts double servo paper feeding control system, which can be used for fish scale paper feeding or single paper feeding. It is convenient and fast with one key conversion

The front lay and side pull gauge have photoelectric detection to ensure the high accuracy of the die cutting

The pneumatic plate locking mechanism can make the plate changing quick and convenient

Imported pneumatic clutch with stable and reliable combination and separation, small braking angle and large torque transmission

Imported Panasonic PLC controller and human-machine interface, digital display of the working speed of the machine, and fault display of the machine make the troubleshooting operation very convenient. Realize automatic control and real-time monitoring of all parts of paper feeding, die cutting and delivery, and cooperate with safety devices of all parts to ensure safe and reliable operation

The die cutting pressure can be adjusted separately front and back, and manual turning is convenient and labor-saving

Automatic paper delivery and flush loading make the paper delivery convenient and orderly

The steel plate suspension function allows the steel plate to be easily pushed in and out

The machine adopts domestic advanced three-dimensional cam indexing mechanism, electric pressure regulating device, pneumatic locking plate, pneumatic sampling and overload protection device. The high-precision main chain drive adopts Germany brand Iwis, pneumatic clutch is also imported

| Item | Specification |

| Maximum paper size (mm) | 1300×980 |

| Minimum paper size (mm) | 500×500 |

| Maximum die cutting size (mm) | 1290×970 |

| Maximum die cutting pressure | 350T |

| Paper weight range | Cardboard ≥200gsm, corrugated board≤8mm |

| Maximum speed | 6000 sheets/per hour |

| Minimum front margin | 8mm |

| Die cutting accuracy | ≤±0.075mm |

| main motor power | 11kw |

| total power | 22kw |

| gross weight | 17T |

| Dimensions | 6150*2300*2260mm(platform not include ) |

At ELITET MACHINERY, you can expect satisfactory customer service with long tradition. We are highly devoted to the most optimal solid and liquid separation solutions to meet your specific needs. We have the effective service system to ensure professional and flexible management of any affairs.

1.Pre-sales technical consultation 2.Model selection

3.Machine guidance 4.On-site commissioning service

5.Operation & maintenance training 6.Software upgrade

7.Maintenance service 8.Quick supply of spare parts

9.Customer satisfaction track

Professional wooden package and skilled loading teams